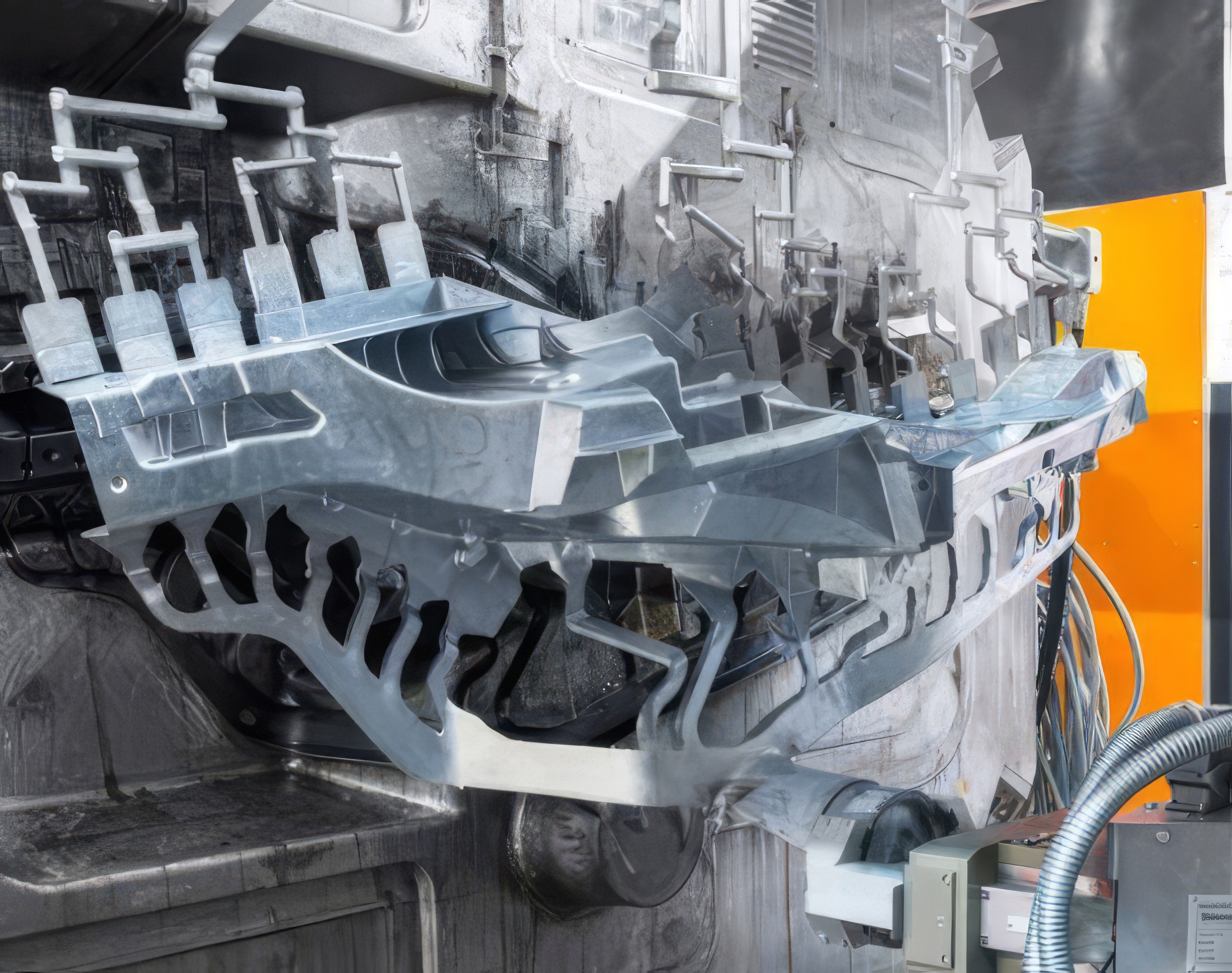

About TwinCAST™

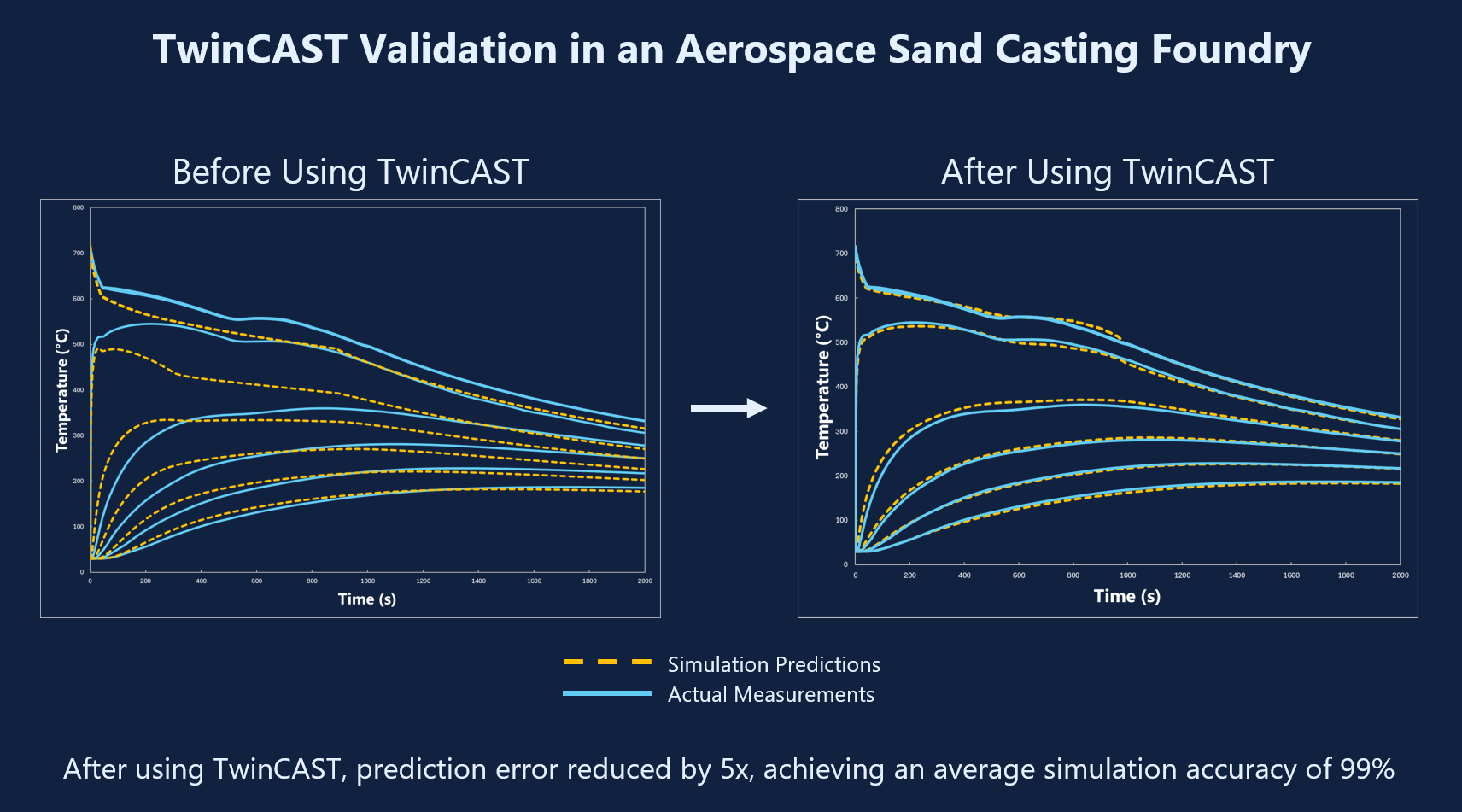

TwinCAST breaks the decades-old "garbage-in, garbage-out" problem in casting simulation—making digital twin results accessible for all foundries.

Our AI-powered software predicts the thermophysical properties of your unique alloy and mold materials that simulations depend on, so predictions will near-perfectly match your real-world castings.

See case study →Value to foundries

- Predict and prevent defects that lead to costly rework and scrap

- Shorten development and production cycles and deliver more castings every year

- Optimize castings and rigging for service requirements, manufacturability, and cost

Explore our solutions →